Recently, a cold wave hit and the temperature dropped sharply. The staff in the Ruima Laser production workshop are still full of energy. They are busy with production according to the production plan to ensure quality and production, anchor the fourth quarter production and assembly goals, and go all out to catch up with the deadline to ensure that the laser equipment is delivered on schedule. On November 23, with the truck entering the factory and setting off, the 6KW cutting equipment purchased by Jiangsu Tianzhiheng was delivered on schedule, witnessing the high-quality after-sales service of Ruima Laser "careful production and assembly, quality and quantity delivery".

![Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines]()

Products are manufactured with precision and orders are coming in one after another

Jiangsu Tianzhiheng focuses on the modular and movable mining box manufacturing of large-scale mines, providing customers with professional and reliable design solutions, and strictly following standard procedures.

![Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines]()

Tianzhiheng Mobile Mining Box

In terms of production and manufacturing, in order to increase its market share, Jiangsu Tianzhiheng urgently needs to solve the problems of excessive reliance on disposable molds, waste of production and manufacturing costs, high time consumption and low energy efficiency. In recent years, Ruima Laser has focused on the technical research and development of flexible processing methods. The cutting efficiency and product precision of its U3 series products have been greatly improved, which not only avoids material waste and labor consumption in the manufacturing process, but also stands out in the manufacturing of porous and complex workpieces. By using software mapping to cooperate with cutting work, no mold is required and secondary processing is avoided, which can achieve efficient manufacturing, greatly reduce production costs, win customer praise, and win this order with precision quality.

Production quality improvement and efficiency increase, mine box "smart" manufacturing upgrade

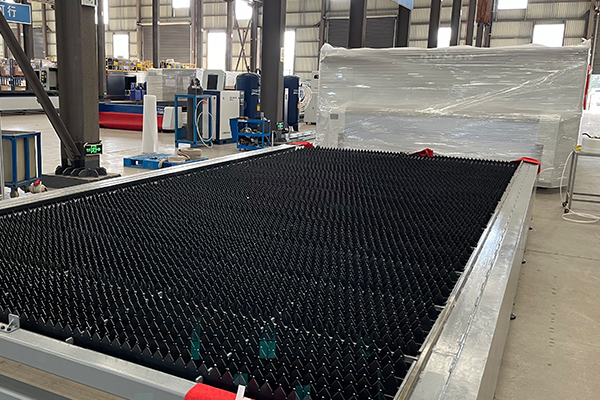

The model purchased by Jiangsu Tianzhiheng this time is RM-C6025APF-6000I. Whether in terms of cutting performance, equipment configuration or energy saving and low consumption, it can help enterprises achieve quality improvement and efficiency increase, and create a revolutionary value experience for production and manufacturing.

![Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines]()

Mobile mine boxes are mainly used for the crushing and screening of various ores, including mineral collection, excavation, loading, transportation and other fields. From the perspective of production and manufacturing technology, they have high requirements for large-format plate cutting capabilities. The Ruima laser purchased by Jiangsu Tianzhiheng this time is equipped with a 6000W laser, and the maximum thickness of carbon steel plate can be cut up to 25mm. It has the advantages of high efficiency, low consumption and low processing cost, and can ensure long-term use accuracy.

![Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines Ruima empowers mining machinery and equipment with 10,000-watt laser cutting machines]()

The manufacturing of mobile mining boxes needs to comprehensively consider the product's structure, performance, applicable scenarios and other factors to ensure that it can meet actual needs and bring better benefits to the enterprise. Therefore, in terms of the detailed configuration of the cutting equipment, the stability and convenience of the equipment are required to be high. The Ruima laser equipment delivered this time has parallel exchange table cutting and loading without affecting each other. The loading process can be completed within 20-30S while cutting, making production and manufacturing more efficient; all core components are high-end European brands with high precision, good stability, extremely low failure rate and long service life; open Ethercat bus control, human-computer interaction interface, and more convenient operation.

10,000-watt cutting expert, quality service customer

Ruima Laser focuses on the "dual carbon" goal of China's manufacturing industry and the overall industry's intelligent, green and environmentally friendly development trend, continuously optimizes the laser cutting process, improves equipment configuration, and helps enterprises optimize and upgrade production and manufacturing. This cooperation with Jiangsu Tianzhiheng is not only the beginning of the cooperation between the two parties, but also a concrete demonstration of Ruima Laser keeping up with the development trend of the industry and helping the intelligent development of the mining box manufacturing industry. Ruima Laser is always on the road to serve customers with precision products and become an expert in the 10,000-watt cutting industry!