Large-format Sheet Laser Cutting Machine

Exchange Platform Sheet Laser Cutting Machine

Single platform metal fiber laser cutting machine

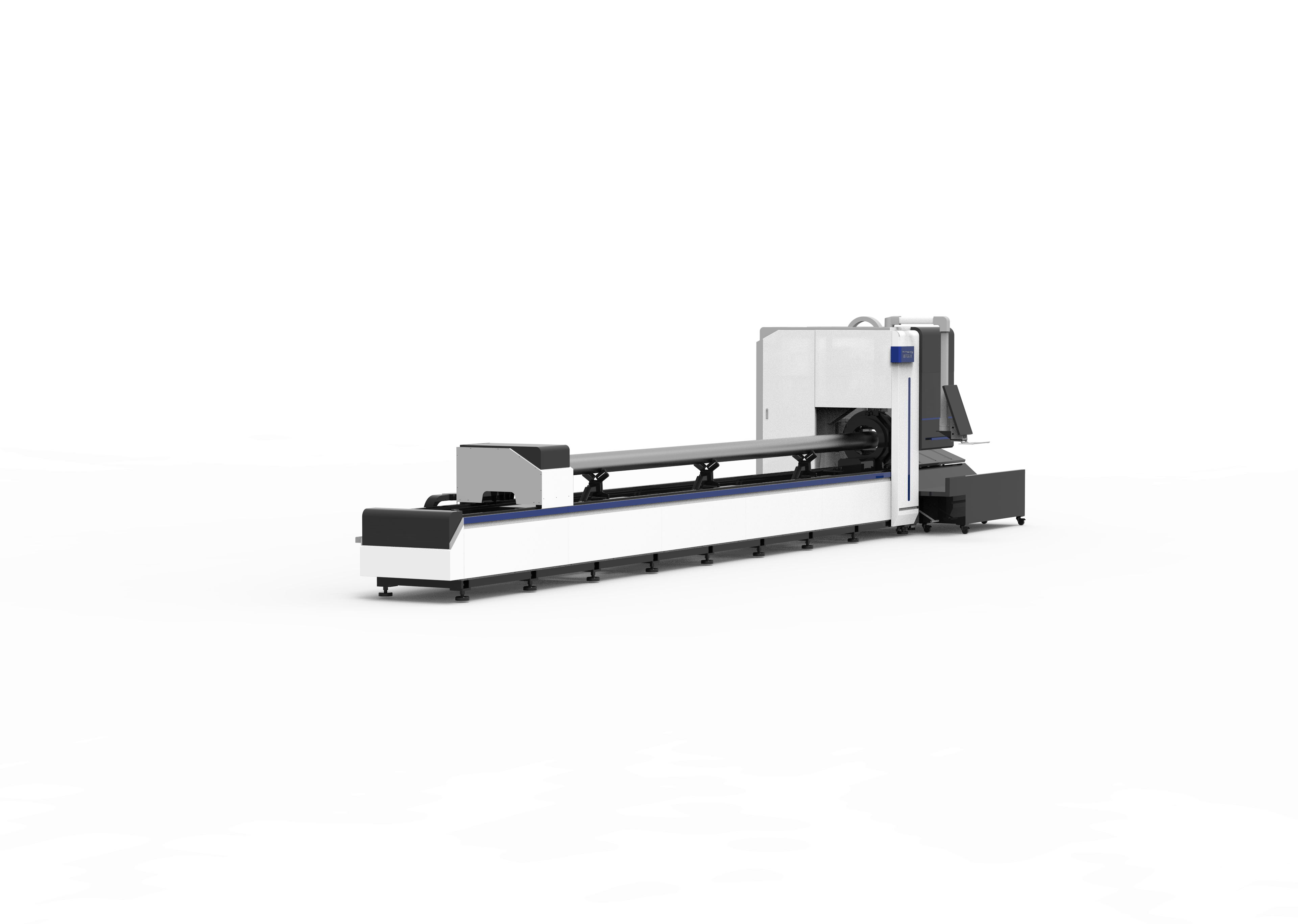

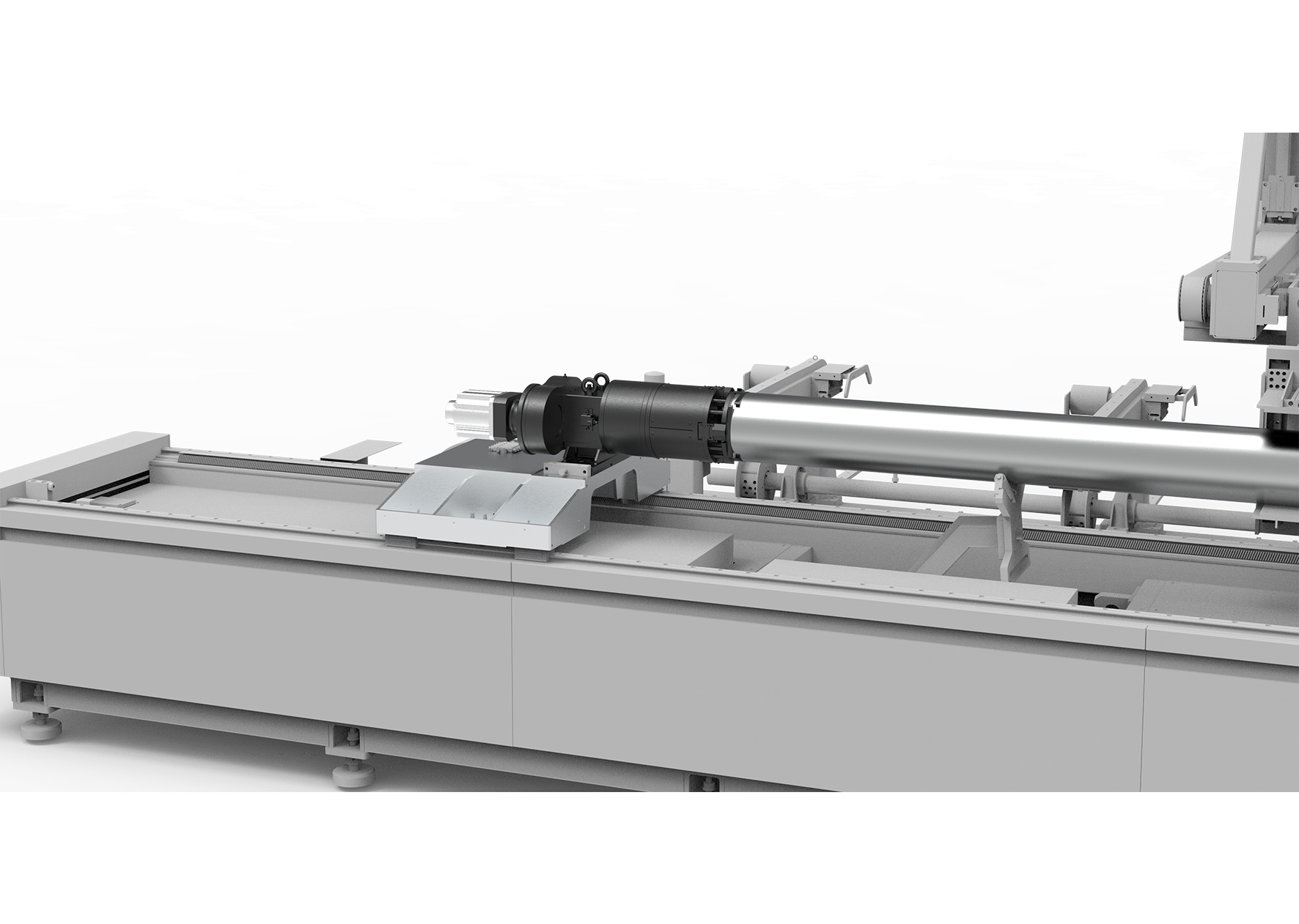

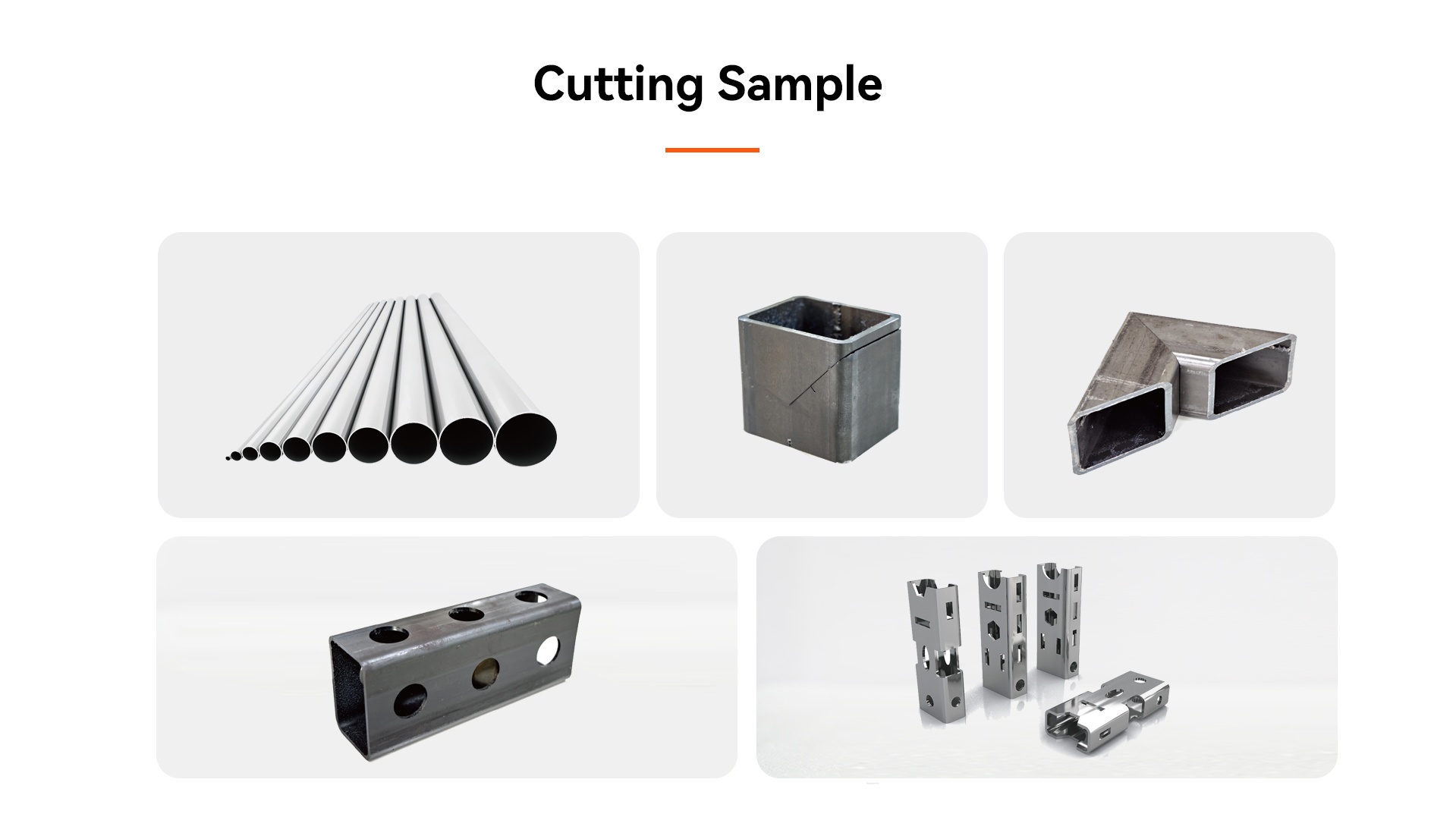

2 Chuck Tube Fiber Laser Cutting Machine

3 Chuck Tube Laser Cutting Machine

4 Chuck Laser Pipe Cutting Machine

H-beam metal laser cutting machine

Plate And Tube Integrated Fiber Optic Metal Laser Cutting Machine

Automatic Coil Laser Cutting Machine

Handheld Welding Machine