Working principle of fiber laser cutting machine

Fiber laser cutting machine is the most popular type of laser cutting machine. The machine uses a fiber laser source and achieves a near-perfect cutting effect. Fiber laser is a solid-state laser that has developed rapidly in the metal cutting industry in recent years.

Simple comparison of CO2 laser and fiber laser

Fiber technology uses solid gain media, not gas or liquid. The "seed laser" produces a laser beam, which is then amplified within the glass fiber. The wavelength of the fiber laser is only 1.064 microns, which can produce an extremely small spot size (up to 100 times smaller than CO2), making it ideal for cutting reflective metal materials.

The fiber laser source can output a high-power laser beam, focusing on the surface of the material, causing the focused area to vaporize or melt instantly. Controlled by the CNC system and the mechanical system, the laser head is moved, the laser spot is changed, and automatic cutting is achieved with fast speed and high precision. Fiber laser cutting has developed into the highest precision laser cutting method today and is widely used in the metal parts processing industry.

Diversity of metal fiber laser cutting machines

Metal laser cutting

Fiber laser cutting machines can process a variety of metal materials, including stainless steel, carbon steel, alloy steel, aluminum, galvanized sheet, copper, silver, gold, etc. Different fiber laser sources can be selected according to the characteristics of the metal.

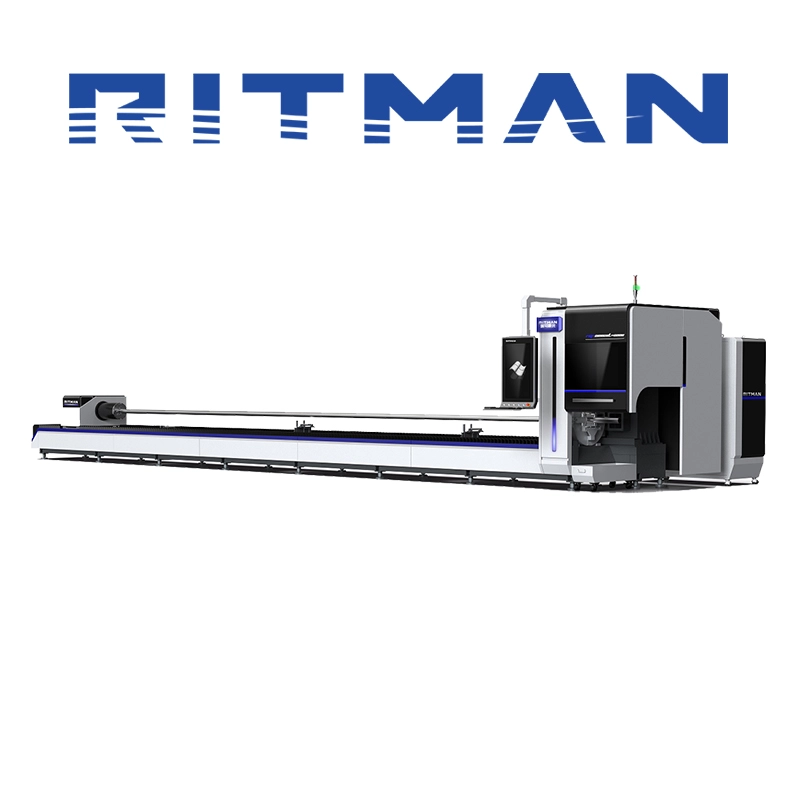

In addition to sheet metal cutting, fiber laser cutting machines can also process special-shaped metals and steel pipes. The machine can be equipped with a steel pipe cutting system to expand its cutting capacity. The blade is neat and smooth, meeting the high requirements in the industry.

Main advantages of fiber laser cutting

• Fiber lasers have a higher energy conversion rate of up to 30%, saving operation and maintenance costs.

• The laser cutting machine adopts semiconductor modular and redundant design, and there is no optical lens in the resonant cavity. Therefore, there is no need to spend a lot of time starting and adjusting the machine before cutting work, which is unmatched by traditional laser machines.

• The fiber laser head is equipped with a protective lens to protect the focusing lens and reduce parts consumption.

• The laser head will not directly contact the material to avoid scratching the material and ensure the cutting effect.

• The fiber laser produces the smallest slit and hot zone, maintains cutting stability, and avoids material deformation.

• 0.2mm/min cutting accuracy and fast cutting speed significantly improve the efficiency of metal parts processing.

• Fiber laser cutting machines work in a safe and environmentally friendly way. The pollution and noise generated are small, and the workshop environment can be better protected.

As a professional fiber laser equipment manufacturer, RITMAN Laser focuses on the manufacturing and technical services of fiber laser cutting machines and fiber laser marking machines.