What are the common alarms of laser cutting machines?

Laser cutting machines often encounter different types of alarms during operation. When an alarm occurs, how should we deal with it properly?

Laser cutting machine alarms mainly include the following three types:

1. Abnormal capacitance alarm

When the capacitance value is 0, abnormally increased or decreased, etc., it is usually recommended to perform manual calibration to solve the problem.

2. Limit alarm of Z axis or fourth axis

If a limit alarm occurs on the Z axis, the general solution is to disconnect the power supply for 5-10 minutes, then reconnect it, and ensure that the machine is zeroed. For the limit alarm of the fourth axis, according to whether it is a positive limit or a negative limit, perform the corresponding addition and subtraction operations until the alarm is lifted and the focus is zeroed.

3. Servo alarm involves each axis

When a servo alarm occurs, first try to restart the device. If the problem is not solved after restarting, it is necessary to locate the corresponding servo drive in the cabinet and find a specific solution based on the code displayed by the servo system.

The above are common alarm situations and corresponding treatment methods for laser cutting machines, but the specific solutions need to be flexibly dealt with according to the actual situation. If you encounter any problems during operation, please contact professional technical support or after-sales engineers in time.

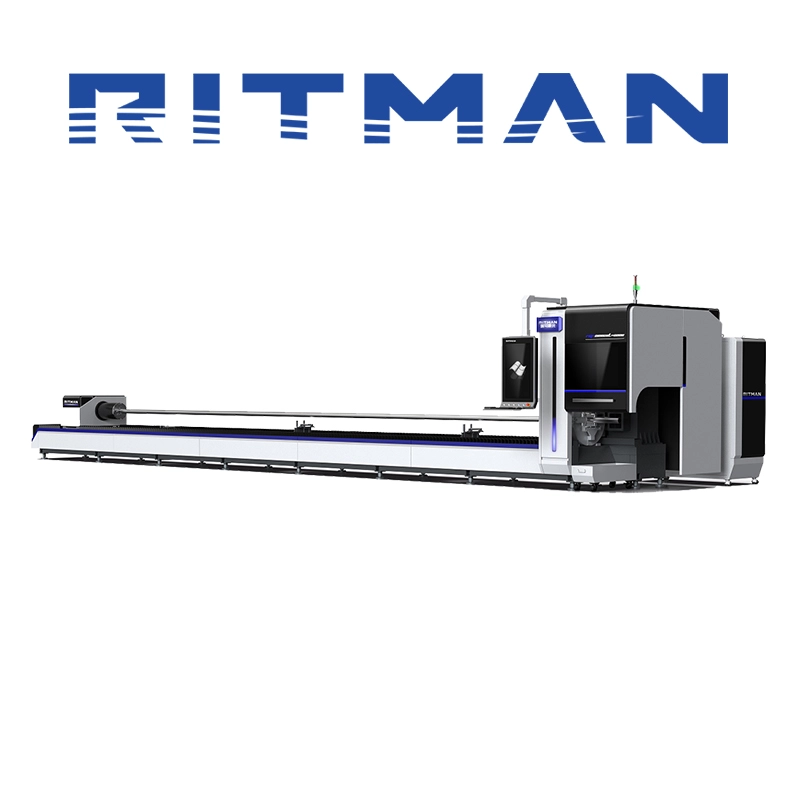

Laser cutting machine High-energy laser cutting technology Plate processing equipment Pipe cutting solution Laser cutting machine professional manufacturer