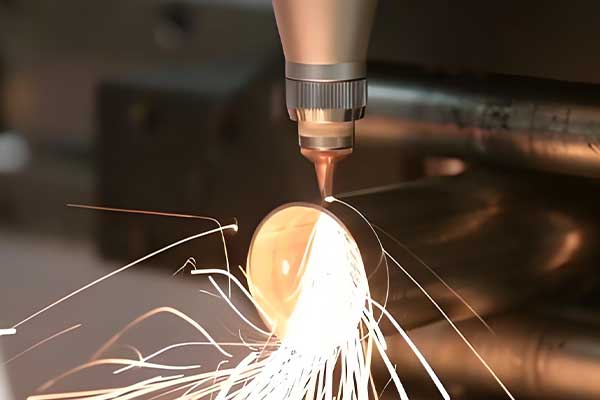

How to deal with the cutting deformation of the laser cutting machine?

The laser cutting machine may indeed cause deformation of the material during the processing process, especially when cutting thicker plates. This deformation is usually caused by the material being heated, pressurized, or both. The degree of deformation depends on many factors, including laser power, cutting speed, material type and thickness, and auxiliary gas pressure.

In order to minimize deformation during the cutting process, the following measures can be taken:

1. Material pretreatment: Proper pretreatment of the material, such as heating or stress relief treatment, can reduce the deformation of the material during the cutting process.

2. Reasonable process parameter selection: According to the type and thickness of the material, select the appropriate laser power, cutting speed and auxiliary gas pressure. Excessive laser power or too low cutting speed may cause the material to overheat and deform.

3. Use a cooling system: Using a cooling system during the cutting process, such as water cooling or air cooling, can help dissipate heat quickly and reduce deformation caused by heat accumulation.

4. Support and clamping: During the cutting process, ensuring that the material is fully supported and clamped can reduce deformation caused by uneven force. Sometimes support points can be added on the back of the cutting path to improve stability.

5. Deformation prediction and compensation: By simulating the cutting process, the possible deformation of the material can be predicted and compensated accordingly when designing the cutting path. For example, when cutting a workpiece with a complex shape, you can first predict how it will deform, and then adjust the initial design to ensure that the final cutting result meets the requirements.

6. Cutting sequence optimization: A reasonable cutting sequence can reduce the deformation of the workpiece during the cutting process. It is usually recommended to cut from the outside to the inside, avoiding cutting inner holes and complex graphics without external support, which can reduce the deflection of the material.

7. Use high-precision laser cutting equipment: High-precision laser cutting machines have more accurate positioning and cutting capabilities, which helps to reduce deformation caused by insufficient equipment accuracy.

If deformation has already occurred, the following methods can be used to deal with it:

- For minor deformation, it can be corrected by manual or mechanical methods.

- For severely deformed parts, it may be necessary to re-cut or abandon it.

- If the deformation is predictable and within an acceptable range, it can be compensated in the subsequent manufacturing process, such as through bending or other forms of shaping.

Deformation does occur during the cutting process of the laser cutting machine, but this problem can be effectively prevented and dealt with through the above measures. It is important to understand the various factors that affect deformation and consider them comprehensively according to the specific situation to achieve high-quality cutting